PARALYMPICS DRESS

HOW I 3D PRINTED AMY PURDY’S DRESS AT THE PARALYMPICS OPENING CEREMONY

THE STORY

I was honored to have been chosen to be the designer of Amy Purdy’s dress for her dance at the Paralympics Opening Ceremony in Rio 2016.

THIS IS THE STORY OF HOW THE DRESS CAME TO LIFE.

In November 2015, the creative team of the ceremony reached out to me to commission a dress for one of their segments. I was ecstatic to get involved in this unique event. It is an incredible opportunity to design a 3D printed dress that will be seen in movement by hundreds of millions of people around the globe.

INSIGHTS

Last touch ups a few days before the ceremony

After my collection “went viral” last year, the creative team discovered my work online and especially liked how the flexible dresses I had printed moved so beautifully.

The dance segment explores the relationship between humans and technology as Amy dances a samba with the KUKA robot, which was fitting because 3D printers are also a type of robot.

I loved the idea of creating a dress for Amy Purdy, a beautifully strong woman who is also a double-leg amputee. With an incredibly strong character and the help of technology Amy can walk, become a Paralympic medalist, dance with the stars, and now dance at this incredibly moving ceremony!

INSPIRATION

Amy contracted Meningitis at the age of 19 and had to have her legs amputated below the knee. In my view, the story of what happened to Amy is like a rebirth.

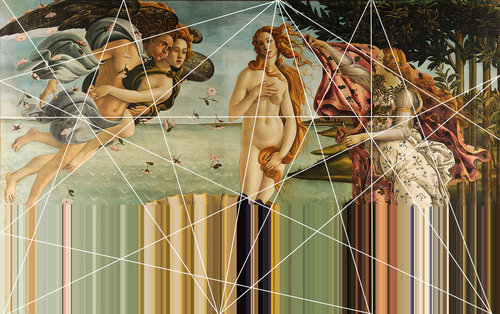

I was inspired by Sandro Botticelli’s painting The Birth of Venus. The many diamond shapes present in the painting’s composition and the nude color of Venus, gave me a direction for the dress.

The Birth of Venus (modified)

THE PROCESS

Last touch ups a few days before the ceremony

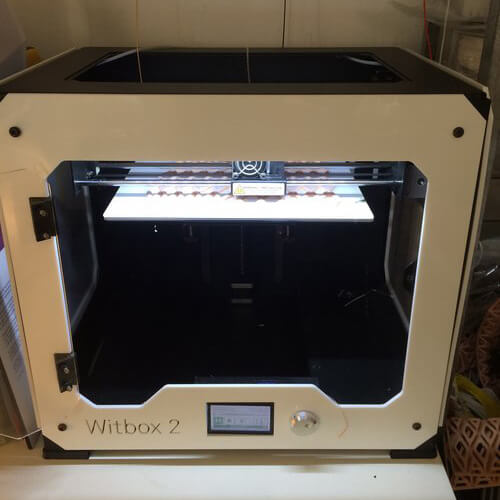

The dress is entirely 3D printed. I used a similar process to the one I had developed last year:

I printed it using a soft material called FilaFlex made by Recreus, a wonderful and innovative company from Spain who helped me a lot with printing time and materials.

I used the new version of the Witbox, which was 3X faster than the one I used last year, so it took me “only” 100 hours to print the dress (as opposed to 300 hours last year).

I worked closely with my partners at Gerber Technology to create a fast workflow to work with two software for pattern-making and 3D modeling: Accumark & Blender. In the near future, Gerber will make it so we can use just Accumark to go from pattern-making to printing.

By printing the soft materials in structures that are flexible, I got the “textiles” I wanted in order to create a dress that moves so beautifully.

MAKING THE DRESS FIT PERFECTLY

I hadn’t met Amy before the first fitting, but just a month before the ceremony. I wanted the dress to fit her perfectly, so I used an app called Nettelo to get Amy’s exact measurements and print a highly personalized dress.

The Birth of Venus (modified)