THE PROCESS

HOW I 3D PRINTED A 5 PIECE FASHION COLLECTION AT HOME

Liberty Leading the People – my inspiration board

MY 3D PRINTING JOURNEY

In September 2014 I started working on my graduate collection for my Fashion Design degree at Shenkar.

The following year, I decided to work with 3D printing, which I barely knew anything about. I wanted to check if it would be possible to create an entire garment using technology accessible to anyone.

So I embarked on my 3D printing journey, without really knowing what the end result would be.

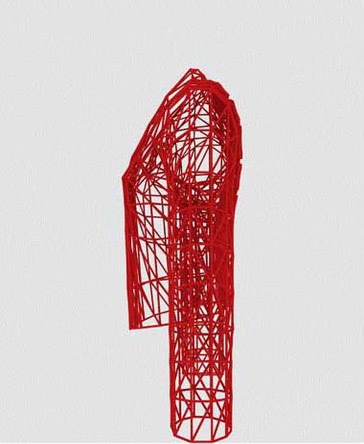

My inspiration was Eugène Delacroix’s Liberty Leading the People. I modified an image of the painting so it would look like a 3D picture. I was inspired to work with the many triangles present in the painting’s composition.

THE LIBERTE JACKET

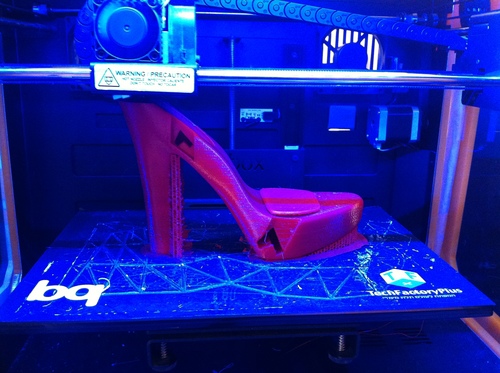

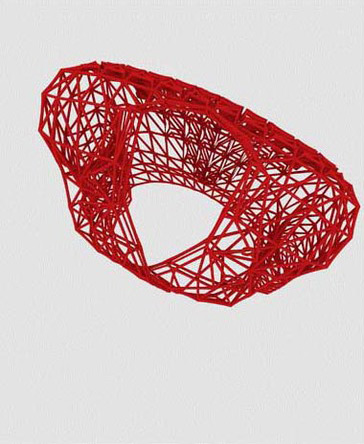

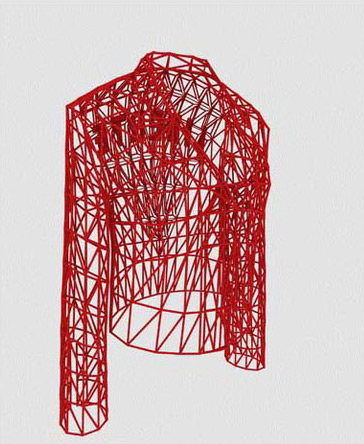

I modeled the jacket using a software called Blender to produce 3D files; this allowed me to start experimenting with different materials and printers. I now find that working with Accumark by Gerber Technology is much more accurate.

3D rendering of my 3D “LIBERTE” jacket

PRINTING TECHNIQUES

I spent a month or so experimenting with PLA, a hard and breakable material. I was not getting very far because the material is inflexible, which is the key property of a “real” textile.

Trying to fix the extruder on the Prusa printers. Michael Layosh is making sure I am doing it right.

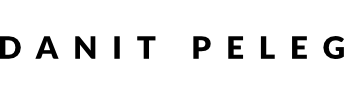

Together with the amazing teams at TechFactoryPlus and XLN, we experimented with different printers (Makerbot, Prusa, and finally Witbox) and materials (e.g. PLA, soft PLA).

Talking about materials with Assaf Perez from TechFactoryPlus

I was really happy to join an incredible global community of makers who share their knowledge, designs, and time to help each other realize their dreams.

Figuring out the right printer configurations at XLN

FLEXIBLE FILAMENT

The breakthrough came when I was introduced to FilaFlex, which is a new kind of filament; it’s strong, yet very flexible. Using FilaFlex and the Witbox printer, I finally was able to print my red jacket.

Though It was great to finally be able to print this flexbile jacket, I also wanted to see how I could create more elaborate textiles for the rest of the collection.

Now that I found the right material, I started experimenting with different types of patterns. I found Andreas Bastian’s Mesostructured Cellular Materials and by combining his incredible structures (and new ones I created with the same approach) and the flexible materials, I could create lace-like textiles that I could work with – just like cloth.

For the black dress, I modified the patterns so that they would have a 3D feel – they now have some “topography” and aren’t just flat textiles.

3D printed textiles!

The first meter of textile

Before and after

Black dress “topographic” textile

SCALING

Once I figured out how to print textiles, I was on my way to create a full collection. It would take more than 2000 hours to print (every A4-sized sheet of textile took at least 20 hours to print) so I had to step up my printer-game, to a full fledged “3D printing farm” at home.

AND SO FINALLY, THE COLLECTION WAS READY…

Just before presenting the collection at Shenkar

AND SO FINALLY, THE COLLECTION WAS READY…

Behind the scenes – just before the runway show

The 5 looks. Photo: Daria Ratiner

CONCLUSION

This has been the most interesting year of my life. When I got started, I wasn’t sure that I would be able to make this happen, but with the help of incredible people I was able to fulfill my dream – to print my own fashion collection!

I really enjoyed the fact that I could create without intermediaries; I could design my own textiles and manufacture my own clothes, all from my own home. I didn’t have to go buy cloth that someone else chose to sell – I could make my own.

I think this is just the beginning. As technologies evolve, we will soon be all printing our own clothes at home.

WHAT’S NEXT FOR ME?

I am thrilled to now be a part of the fashion and technology industries, as a result of my journey/process and would love to work with other fashion designers who want to experiment and research new ways of creating fashion using 3D printing.